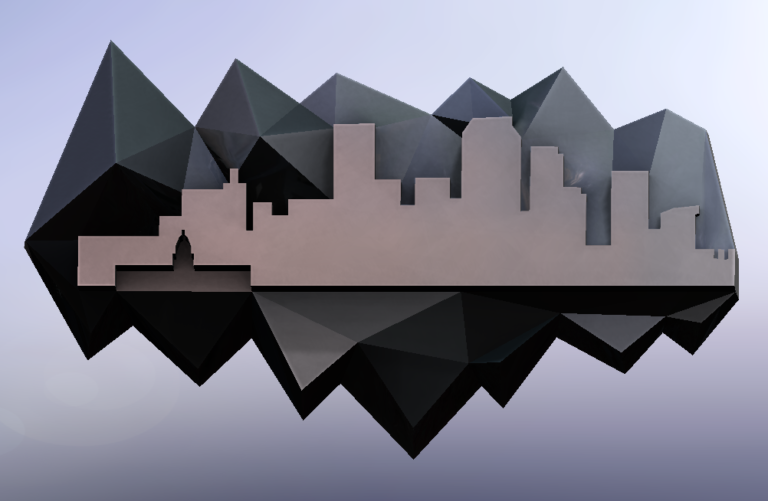

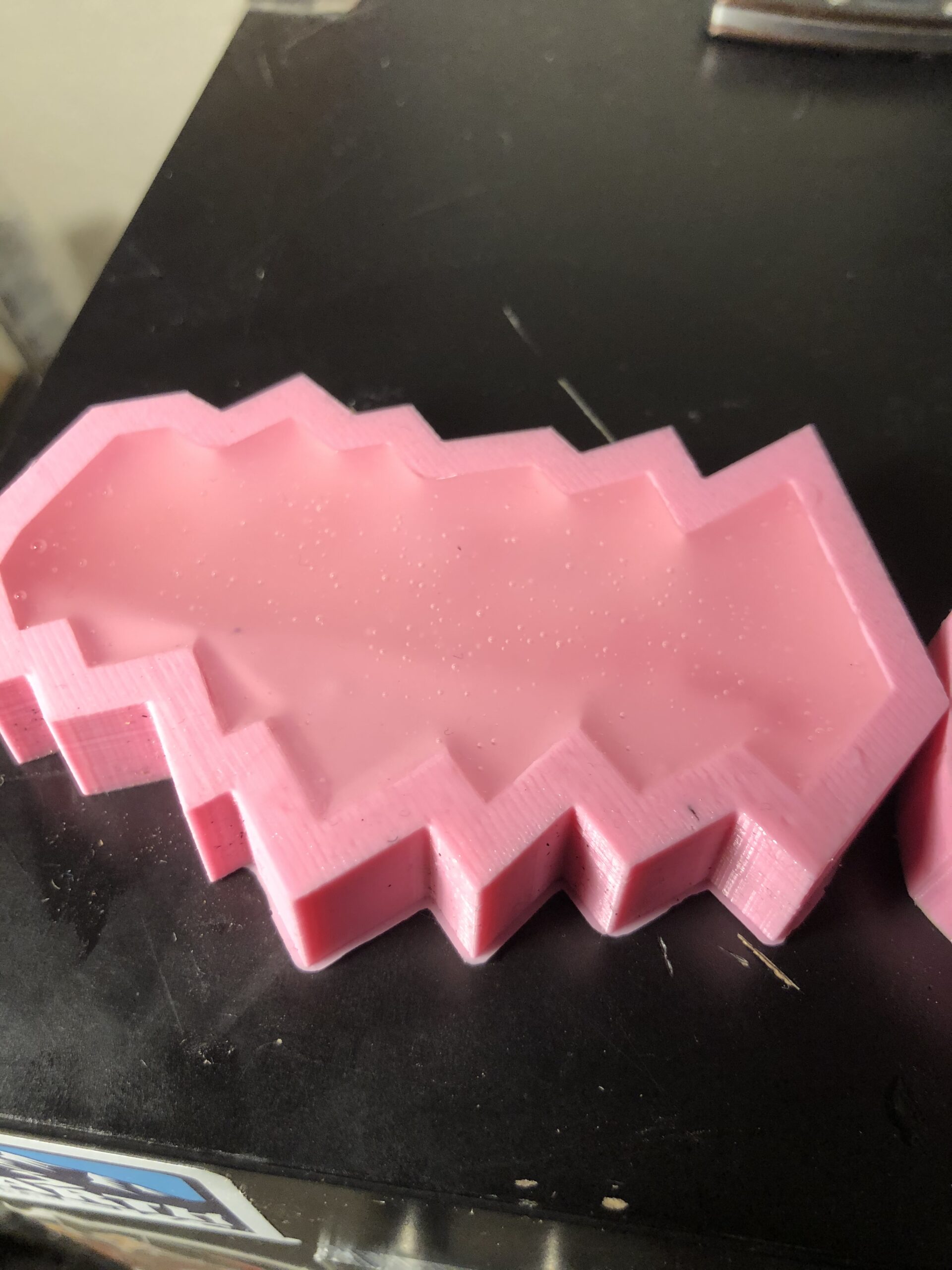

Designed and fabricated a custom snowboard stomp pad using a 3D-printed master pattern, silicone mold tooling, and cast urethane. The project focused on translating a geometric traction pattern into a durable, cold-resistant molded part suitable for outdoor use. The workflow included CAD design, additive manufacturing of the master, mold design and casting, and urethane part production, resulting in a functional traction pad with consistent geometry and surface finish.